Construction equipment is vital for infrastructure development, but with power and productivity comes responsibility. Ensuring the safety of operators, workers, and the worksite is non-negotiable. That’s why construction machinery must adhere to internationally recognized standards like ISO, national regulations like BIS in India, and additional site-specific safety requirements.

At Kaushik Engineering Works, safety is a priority, and understanding these standards can help manufacturers, contractors, and site managers operate efficiently while minimizing risks.

Why Safety Standards Matter for Construction Equipment

Construction sites are inherently risky environments. From cranes lifting heavy loads to excavators moving earth, there is a constant potential for accidents. Safety standards are designed to mitigate these risks by providing guidelines for design, manufacturing, operation, and maintenance of machinery.

Adhering to safety standards has multiple benefits:

-

Protects workers: Reduces the likelihood of injuries and fatalities.

-

Minimizes downtime: Safe equipment experiences fewer breakdowns and accidents.

-

Legal compliance: Meets regulatory requirements, avoiding fines and penalties.

-

Enhances reputation: Manufacturers and contractors known for safety are trusted by clients and employees alike.

Without standardized safety protocols, machines may pose unpredictable hazards, making compliance essential not only for legal reasons but also for operational efficiency.

ISO Standards for Construction Equipment

The International Organization for Standardization (ISO) is a globally recognized body that defines safety and quality standards across industries, including construction machinery. ISO standards ensure that equipment is reliable, safe, and compatible across international markets.

Some key ISO standards relevant to construction machines include:

-

ISO 9001: Focuses on quality management systems to ensure equipment meets performance and safety expectations.

-

ISO 12100: Provides general principles for risk assessment and risk reduction in machinery design.

-

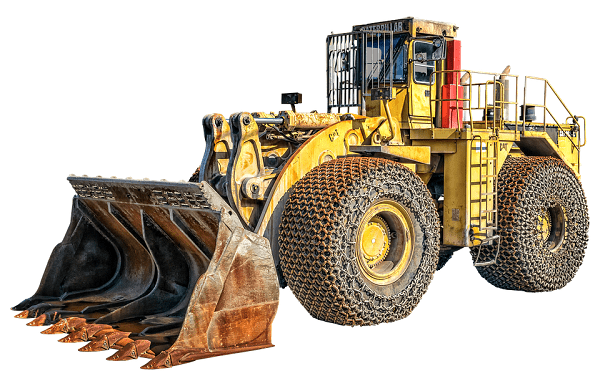

ISO 20474: Specifies safety requirements for earth-moving machinery.

-

ISO 3691-4: Governs safety requirements for industrial trucks used on construction sites.

By designing equipment according to ISO standards, manufacturers ensure that machines not only perform efficiently but also safeguard the health and well-being of operators. These standards are particularly valuable for companies that export equipment internationally, as compliance ensures acceptance in multiple countries.

BIS Standards for Construction Equipment in India

In India, the Bureau of Indian Standards (BIS) plays a similar role, establishing safety and quality benchmarks for industrial and construction machinery. BIS standards are aligned with national regulations and help manufacturers produce machinery that is safe for Indian conditions.

Key BIS standards for construction equipment include:

-

IS 9434: Safety requirements for hydraulic excavators.

-

IS 4030: Safety specifications for cranes and lifting equipment.

-

IS 6759: Guidelines for earth-moving machinery such as loaders and bulldozers.

Manufacturers adhering to BIS standards demonstrate their commitment to safety, ensuring that their machines are compliant with legal requirements and suitable for the diverse operating conditions across India.

Site-Specific Safety Requirements for Construction Equipment

While ISO and BIS standards provide general safety frameworks, each construction site may have unique risks requiring additional precautions. Site-specific safety standards consider:

-

Terrain and environment: Uneven ground, mud, or waterlogged areas may require special machine modifications.

-

Load requirements: Overloading can cause machinery failure or accidents.

-

Local regulations: Municipal or state guidelines may impose additional safety measures.

-

Worker safety protocols: Protective gear, training, and emergency response plans are tailored for site conditions.

For example, a high-rise construction site may require machines with fall protection systems and advanced braking mechanisms, whereas a road construction site may prioritize vibration reduction and dust control. Manufacturers and site managers must work together to implement these additional safety measures.

What Manufacturers Must Do to Ensure Compliance

Manufacturers of construction equipment bear significant responsibility to ensure their machines meet all relevant safety standards. Compliance is not just about certification; it involves a holistic approach:

-

Design Safety into Equipment: Incorporate fail-safe mechanisms, emergency stops, and protective guards from the early design stages.

-

Conduct Risk Assessments: Identify potential hazards and develop strategies to mitigate them, following ISO 12100 guidelines.

-

Adhere to Quality Management Systems: Implement ISO 9001-compliant processes to ensure consistent quality and safety in production.

-

Regular Testing and Certification: Machines should undergo rigorous testing and obtain certifications from BIS, ISO, or other recognized authorities.

-

Operator Training: Provide manuals, safety guidelines, and hands-on training to operators to ensure proper usage.

-

Maintenance Protocols: Schedule regular maintenance and safety inspections to prolong equipment life and prevent accidents.

By embedding safety into every stage of manufacturing and operation, companies can protect workers, avoid regulatory penalties, and enhance the durability and reliability of their machines.

Key Takeaway

Safety standards for construction machinery are not optional—they are essential for protecting lives, ensuring compliance, and maintaining operational efficiency. From global ISO standards to India-specific BIS regulations and site-specific safety requirements, manufacturers and contractors must stay vigilant and proactive.

Implementing these standards requires a collaborative approach between manufacturers, site managers, and operators, ensuring machines are safe, reliable, and productive under all conditions.

Ensure Safety and Efficiency with Kaushik Engineering Works

At Kaushik Engineering Works, safety and quality are at the heart of everything we do. Our construction machines are designed and manufactured to meet ISO and BIS standards while incorporating site-specific safety requirements.

We help clients operate machinery that is not only efficient but also reliable and safe, protecting both workers and investments. By choosing Kaushik Engineering Works, you ensure compliance, productivity, and peace of mind on every construction project.

Read more about our commitment to safety and innovation: Kaushik Engineering Works – Construction Equipment Safety Standards